The School of Art + Design (A+D) prides itself on its students' creativity and rigorous exploration of their degree programs, focusing on creating an active community of creatively and critically engaged artists and designers. The work is rigorous as the students study across a uniquely broad set of studio practices that challenge students to think, make, see, and question. This pedagogy combined with the hands-on faculty and interdisciplinary collaboration rewards students with unique opportunities to submit their work to national competitions. Faculty identify competitions that fit each student's skill set and interests. This award-winning work is celebrated by both the college and the school, and the most recent project from Product Design (PD) student, Eli Mikiten PD '25, is just one example of the type of thoughtful, purposeful projects students complete in their degree program with the help of their professors and instructors.

"I think one thing that really surprised me was just how much our professors wanted to get to know us," said Mikiten. "Yes, they're here to critique you and be a strong guiding force, but you'll see them on campus and they will come over to talk about your projects and see how you are doing."

Mikiten was especially effusive in his praise for Product Design Career Instructor Tom Bonamici and Product Design Associate Professor, Erdem Selek.

"If you're seeking portfolio advice or want to learn about the world of being a designer, Tom and Erdem are the people you can turn to for those insights. They are professors you look forward to seeing every day in class, being around professors who have that 2 U of O A&D Eli Mikiten much knowledge to share is amazing. The environment they both cultivate in the classroom is truly special."

PD students learn to apply their art and design skills to fit a changing world. Individuals in the program learn to design objects for use across a broad range of scales and purposes. This includes designing for a myriad of different areas from tools to transportation to technology to clothing to furniture to sporting equipment, creating well-versed designers for every industry. Collaboration is a major focal point for students in the degree program and the university's resources help fuel the individual's novel design process.

"You can always approach one of your buddies in a business program and say, 'Hey, what do you think about this idea?' Or, you know, if you're working on ceramics, you can head over to the Earth Sciences department and ask them some questions about where these different materials are coming from and how you can use them," explained Mikiten. "You don't get that kind of opportunity at a small school. The resources here have so much to offer across the board, and there are so many bright minds that want to talk, collaborate, and share knowledge. I mean, there aren't many environments like that. A+D delivers a supercharged design atmosphere and has been making a paradigm shift towards being a highly respected product design program, especially on the West Coast."

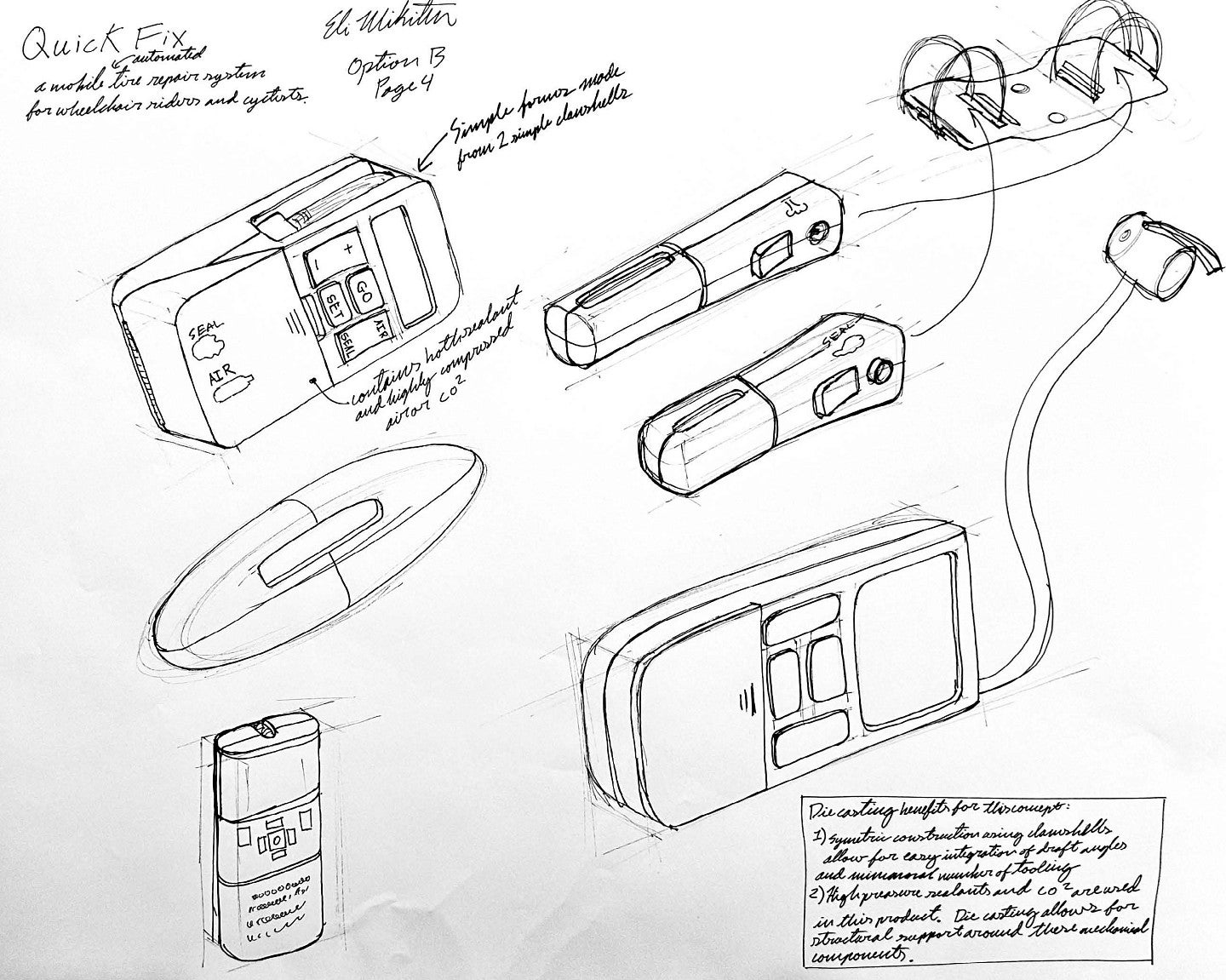

Mikiten, under the guidance of Bonamici, showcased this collaborative, flexible thinking with his award-winning project for the 2023 International Zinc Challenge, Verve. Verve is a portable, hand-held inner tube sealer and tire pump designed to provide a novel solution for wheelchair riders who often experience flat tires when traveling on and off the beaten path. Verve's main function is to help riders keep rolling in situations where a flat tire could leave an individual stranded. Using a built-in replaceable tire sealant canister to quickly and effectively deliver sealant, Verve fills a need for an underserved population that many might not consider when creating a solution for flat tires. Due to his own personal experience and collaborations, Mikiten identified a unique need for his design for the International Zinc Challenge and was praised by the judges for its "well-justified alloy selection" and novel design.

"I have a rare genetic condition called osteogenesis imperfecta or OI," said Mikiten. "It's pretty rare, but my dad, my grandfather, and I all have it. I've been in and out of a wheelchair my whole life, and that's a big reason why I'm pursuing product design. Hopefully, in my future, I can apply my understanding of the world as a person living with a disability to the product design field. For the International Zinc Challenge, which focused on human-powered micro-mobility, I drew upon my experiences. Wheelchairs are often overlooked in the realm of human-powered transportation, so it was gratifying to incorporate my lifelong experiences into the challenge. The result was a small, handheld, battery-powered device—an automatic tire pump—that can seal tires and re-inflate them quickly, addressing a challenge my dad, myself, and other wheelchair users face regularly when left stranded by punctures while traveling or exploring off the beaten path. This project resonated with me on a deeply personal level and was incredibly fulfilling."

The Verve features an extendable pump head that allows easy access to tire valves located between spokes. The on-board pressure monitor and computer target the required pressure, displaying the target and current pressure on the monitor. LEDs are built-in to the case for easy viewing of sealant and battery levels for all users regardless of vision. This innovative solution that breaks down the barriers for mobility device users was created thanks to the department's access to this annual competition. By encouraging its students to compete, the department is giving its students a low-risk opportunity to experience what it means to be a professional designer.

"The International Zinc Challenge is a competition usually entered annually by students taking PD350, a manufacturing techniques class," explained Mikiten. "The International Zinc Association, which serves as a figurehead body for zinc as a material, encourages design students to create designs around the process of zinc die-casting. It's a great opportunity because it offers valuable insight and experience into the professional work of a designer. When you're working for a client, you often face strict parameters regarding the desired end product. What was particularly beneficial about participating in this challenge is that we were provided with those parameters, which in turn created a bit of a struggle for us to find our creative outlet within them. As designers, our creations never exist in a vacuum. We will always be constrained by production techniques, materials, costs, and design trends. The International Zinc Challenge and the PD350 class offered us a great opportunity to design within a set of parameters while still incorporating our own stories and representation into a design.”

Mikiten was honored in late 2023 for his project by both the Industrial Designers Society of America (IDSA) and the International Zinc Association for his hard work and flexible thinking.

Read More