University of Oregon product design undergraduate student Derek Sackmann is one of just three national award winners in a design competition to develop a lifting device made from zinc, winning $2,000 for himself and $1,000 for the Product Design Program at the UO’s School of Architecture and Allied Arts.

The 2014-5 Interzinc Design Challenge attracted entries from schools across the United States and Canada. The annual competition, which requires zinc for the main component, challenged students this year to develop a lifting device designed to be produced in die-cast zinc.

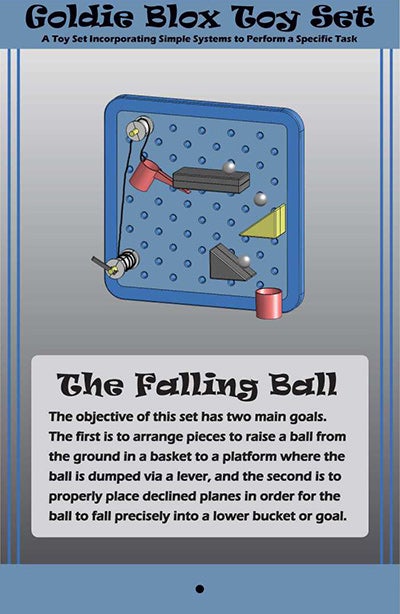

Sackmann’s win is the seventh for UO, which has had a winner in the competition every year it has been offered (including having two winners in 2010-11). His project was titled “Goldie Blox Toy Set, The Falling Ball.”

Competition entrants were asked to design and develop “any type of lifting device.” The design needed to take advantage of the physical characteristics of zinc and not require an electrical power source such as a battery to operate. Entrants were also required to explain why zinc die-casting was the preferred process and zinc the most suitable material for the manufacture of their design.

Sackmann’s design is subtitled “A Toy Set Incorporating Simple Systems to Perform a Specific Task.” The Falling Ball has two main goals: to arrange pieces to raise a ball from the ground in a base to a platform, where the ball is dumped via a lever. The second is to place declined planes in proper order so the ball falls precisely into a lower bucket or goal.

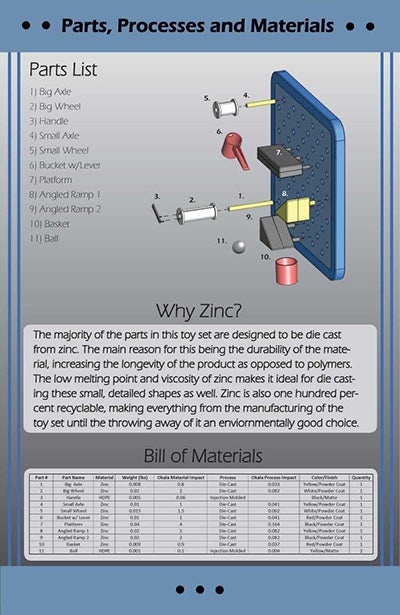

His reasons for using zinc were its durability, which would increase the product’s longevity, and zinc’s low melting point and viscosity, making it ideal for die casting small, detailed shapes. Sackmann also noted that zinc is “one hundred percent recyclable, making everything from the manufacturing of the toy set until the throwing away of it an environmentally good choice.”

A common denominator in UO’s outstanding Interzinc performance is Associate Professor Kiersten Muenchinger, the Tim and Mary Boyle Chair in Material Studies and Product Design at UO. She uses her winter-term Objects and Impacts class for the competition. In the class, students “learn how to redesign an object, think about manufacturing design requirements, and create a suitable entry for the competition,” she says.

The judging criteria was based on the score and completeness of a quiz portion of the entry and the appropriateness of the solution to the design problem including, but not limited to, quality, originality, thoroughness and the development potential.

Work by all winning designs can be seen on the Interzinc website.

UO’s Product Design Program will have 150 undergraduates enrolled when fall term begins Sept. 29.

Above: Images courtesy Derek Sackmann.